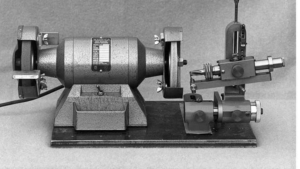

Grinding machines :

A grinding machine is a power-operated machine tool where the workpiece is fed against a constantly rotating abrasive wheel to remove the thin layer of material from work.

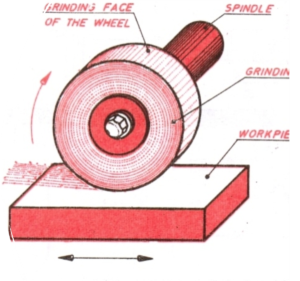

Grinding Wheel :

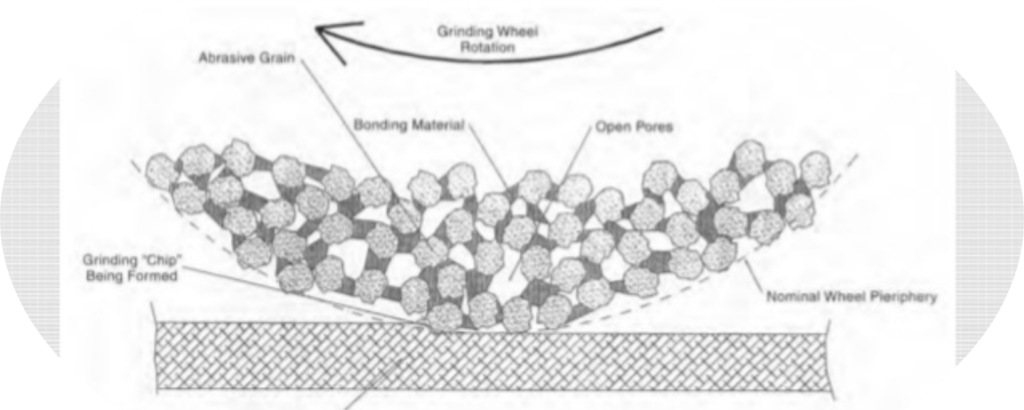

• A grinding wheel is a multi-tooth cutter made up of many hard particles known as abrasives which have been crushed to leave sharped edges for machining

• Every grinding wheel has two constituents:

• Abrasive used for cutting

• Bond that holds the abrasive materials

Functions of Grinding Wheel :

- Removal of stock

- Generation of flat, curved and cylindrical surfaces

- Production of highly finished surfaces

- Cutting off operations

- Production of sharp edges and points

Principle of the grinding process:

• The workpiece is fed against the rotating abrasive wheel.

•Due to the action of rubbing or friction between the abrasive particles and workpiece material is removed.

Purpose of grinding:

•Grinding is a surface finishing operation where a very thin layer of material is removed in the form of dust particles.

• The thickness of the material removed is in the range of 0.25 to 0.50 mm.

• The tool used is an abrasive wheel.

Grinding process :

Grinding is an abrasive machining process that uses a grinding wheel as the cutting tool.

Abrasives :

- Abrasive is the material employed for sharpening, grinding and polishing operations.

- Natural abrasive – emery, corundum, quartz, sandstone, diamond, etc.

- Artificial abrasive – carborundum, aloxite, alundum, etc.

Applications of abrasives:

Corundum :

- It is a natural mineral consisting of aluminium oxide. Hardest natural substance after diamond.

- Used for shaping, finishing and polishing other tools.

Emery :

- natural abrasive consisting of aluminium oxide and a small amount of iron oxide.

Silicon carbide :

- Synthetic abrasive is harder than aluminium oxide.

- Used to grind metals like iron, brass and soft bronze.

- Used in non-metals like wood and leather industries.

Zirconia aluminia :

- It is a mixture of zirconium oxide and aluminium oxide.

- Used in casting and foundry industries.

Cubic boron nitride :

- It is made up of boron nitride with a cubic crystalline structure.

- Used for hard coating material.

Diamond :

- Industrial diamonds are used in grinding wheels as an abrasive material. These diamonds are specifically processed for industrial applications, rather than for jewellery.

Thanks for reading!